Efficiency and Performance: The Advantages of Rotomolded Plastics

Plastic-type is a huge important element in our lives for a long time, from packaging supplies to play ground gear, and health-related gadgets to auto parts. However, the manufacturing of plastic-type material goods has become traditionally dominated by methods such as shot molding, blow molding, and thermoforming. But today, we are going to check out the ability of Rotomolding, which contains revolutionized plastic-type manufacturing with its exclusive properties and impressive techniques.

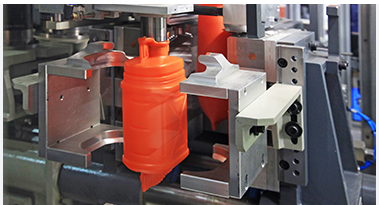

Rotomolding, also known as rotational molding, is actually a relatively new producing strategy that concerns the home heating of your hollow fungus with an axis, then incorporating the required material. The mold will be rotated, resulting in the substance to equally coat the inside the mildew mainly because it cools down and solidifies. This method produces a easy, hollow item, which can be created in a range of styles and sizes, from little playthings to huge tanks.

One of many significant advantages of Rotomolding is being able to use a wide array of resources, such as PVC, nylon material, and polyethylene. This means designers have the flexibility to make customized goods with unique qualities, like UV resistance, chemical level of resistance, conditions opposition, and fire-retardancy. In addition, Rotomolding is well-suited for producing prototypes or short generation works, that may decrease expenses and accelerate the improvement process.

One more key benefit of Rotomolding is its cost-effectiveness. As opposed to injection molding or blow molding, which entail important upfront assets in molds, Rotomolding only takes a individual fungus, that may be used again for a large number of periods. This results in lower tooling costs, producing Rotomolding an expense-successful means for creating big or complicated products.

As said before, Rotomolding is great for producing large and intricate shapes. Since the substance is distributed uniformly over the fungus, it makes it possible to make hollow things that could be difficult or difficult to produce making use of other approaches. The process also permits fuller surfaces compared to other methods, that will make goods stronger and immune to wear and tear.

The exclusive properties of Rotomolding ensure it is particularly suited for producing a range of goods, which include normal water tanks, garden furniture, play ground products, health-related devices, and gardening gear. Because the need for tailored and sturdy merchandise develops, the application of Rotomolding is becoming a lot more widespread in different sectors.

short

In summary, the skill of Rotomolding has revolutionized the way we consider plastic material production, offering an array of rewards and options that conventional methods cannot match up. It is really an exciting and progressive strategy that includes a important long term in several industries’ producing procedures. So, it’s definitely worth exploring the ability of Rotomolding and just how it can reward your business’s demands, regardless of whether it’s through quick prototyping or sizeable-scale creation works.