-

The Revolution of Rotomolding: Engineering Plastic Excellence

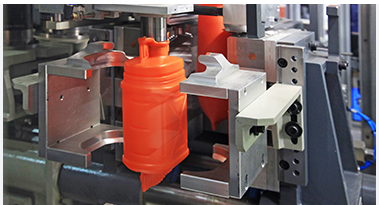

Rotomolding, often known as rotational molding, is really a producing method used for generating plastic-type items. It requires home heating a hollow fungus, filled up with plastic-type material resins, and revolving it around two axes to produce the preferred shape. This production approach has come a long way since its beginning within the 1940s, with numerous Rotomolding advancements in modern technology and components. In this post, we will get a closer look at a few of the latest breakthroughs in rotomolding methods who have revolutionized the plastic engineering market. Multiple-Layering Technology: Multiple-layering technologies is amongst the most recent innovations in rotomolding. It requires layering various kinds of plastic resources to…

-

Rotomolding Materials: Choices and Considerations

Rotomolding, also referred to as rotational molding, is really a developing process when a hollow plastic-type portion is actually created by home heating the molding material in the mildew that involves two perpendicular axes. This technique is normally accustomed to produce hollow plastic-type goods with sophisticated designs, which includes playthings, storage containers, and storing tanks. Just about the most crucial variables that decide the prosperity of the Rotomolding process is your selection of the proper substance. In this post, we’ll check out many of the most common supplies found in Rotomolding and talk about important factors when picking them. Polyethylene (PE): Polyethylene is considered the most typical materials in Rotomolding…

-

Efficiency and Performance: The Advantages of Rotomolded Plastics

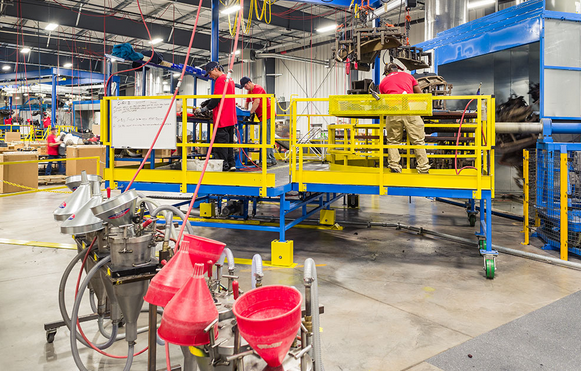

Plastic-type is a huge important element in our lives for a long time, from packaging supplies to play ground gear, and health-related gadgets to auto parts. However, the manufacturing of plastic-type material goods has become traditionally dominated by methods such as shot molding, blow molding, and thermoforming. But today, we are going to check out the ability of Rotomolding, which contains revolutionized plastic-type manufacturing with its exclusive properties and impressive techniques. Rotomolding, also known as rotational molding, is actually a relatively new producing strategy that concerns the home heating of your hollow fungus with an axis, then incorporating the required material. The mold will be rotated, resulting in the substance…

-

The significance of Procedure and Advantages in Rotomolding

Rotomolding is an manufacturing process which can be used to create hollow, smooth plastic components. The procedure consists of warming plastic-type pellets until they can be fluid Plastics Rotomolding enough to fill in to a mold. When the desired form has been created within the mold, it would then need to amazing for many hours before it’s completely ready to take out in the fungus and employ. The rotational molding process is like the brand implies: the liquid resin along with other supplies are rotated to make a part. The rotation method can be achieved by hand or with equipment that can it for you. Rotomolding has numerous positive aspects…